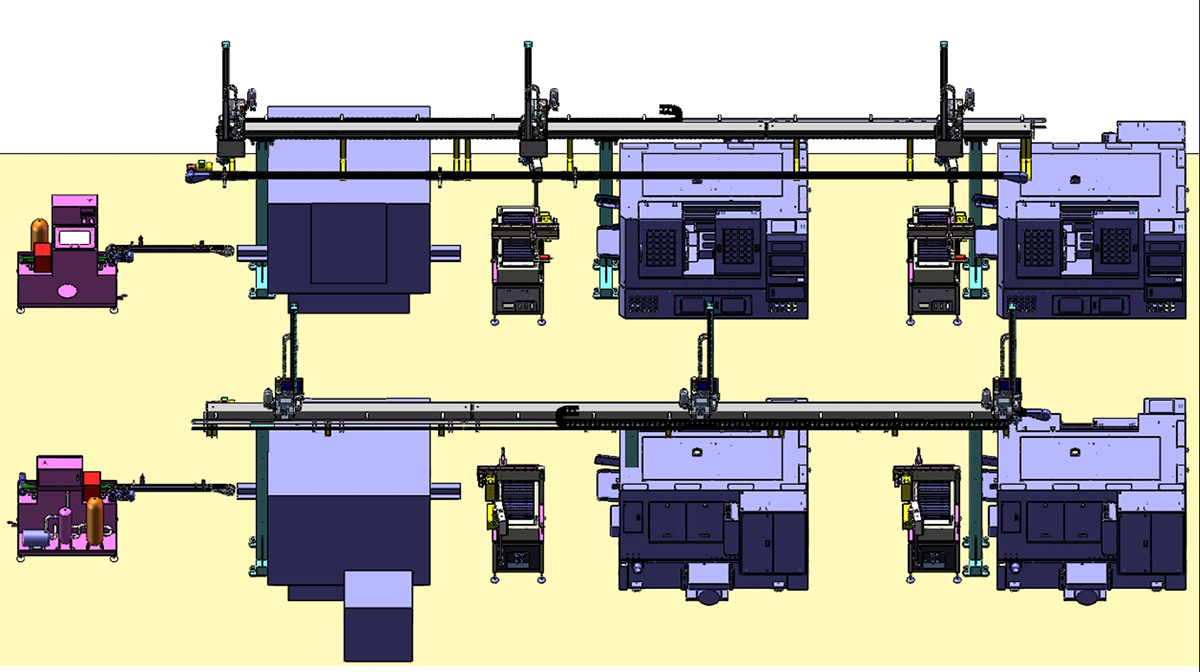

Bearing Rings Grinding Processing Production Line

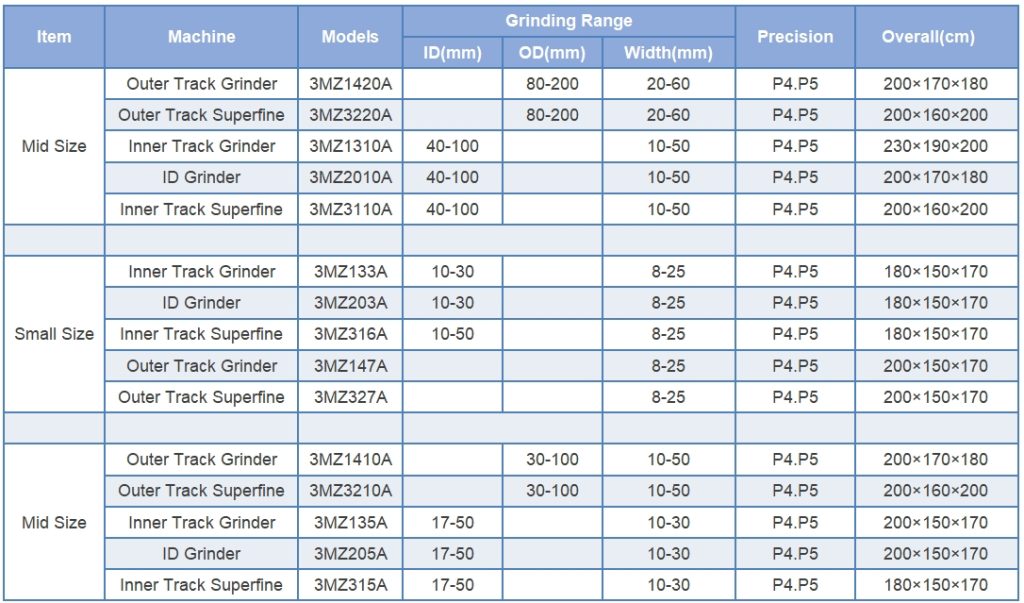

The Bearing rings grinding production line is available for processing all kinds of bearings of inner rings and outer rings and outer diameter of bearing rollers elements , the grinder line can achieve higher stability, higher efficiency, higher precision, higher automatically. and largely increase the productive capacity.