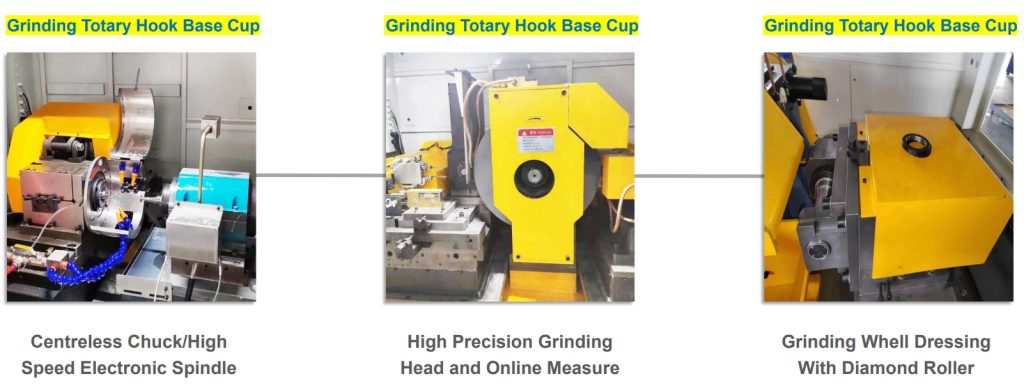

CNC Grinder for sewing rotary shuttle hook

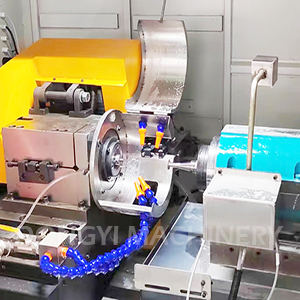

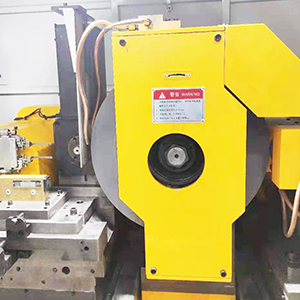

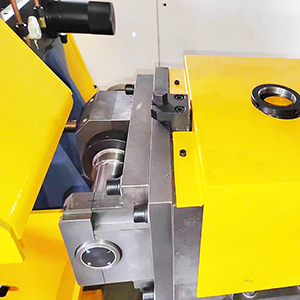

The models serials include the 3MZ14 model and 3MZ13 model , which the serials are available for processing the sewing machine rotary shuttle hook of inner rings(inner cup) and base rings(outer cup) separately, the both grinder were adopted advanced Mitsubishi control system, electronic, pneumatic, hydraulic, automatic online detection integration function, replaceable fixture technology and improvement device, with online tracking detection work piece processing status, to achieve the high-tech precision grinding for inner track of rotary hook , the model has strong grinding rigidity, flexible and reliable operation, high production efficiency, low noise, high processing precision.