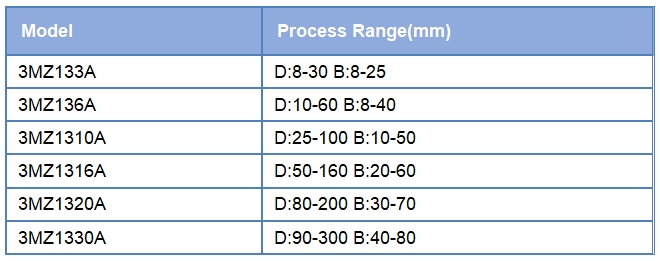

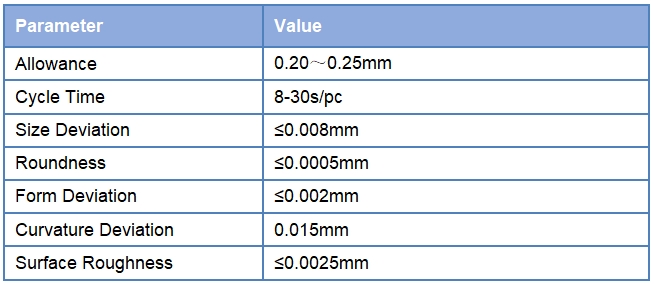

CNC Precision External Grinding Machine

The precision external grinder mainly be used in grinding various bearing rings surface, which is the most refined technology for inner track of bearing ring grinding and external grinding, grinding products includes the deep groove ball bearing ring, angular contact bearing, tapered roller bearing, cylindrical roller bearing and all kinds of components surface, the model can achieve the higher tolerance accuracy and better surface finish of bearing ring. and has higher precision, higher stability, higher efficiency.