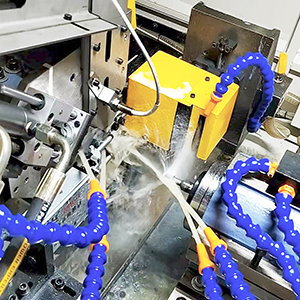

Automatic Bearing Bore Grinding Machine

The automatic bearing bore grinding machine is using the advantage technology for process the bore of bearing ring and various kinds components, the grinding object includes the ball bearing ring, angular contact bearing , tapered roller bearing, cylindrical roller bearing etc, the model can achieve the higher tolerance accuracy and better surface finish of bearing ring. and has higher precision, higher stability, higher efficiency in bearing industry and automation energy industry.