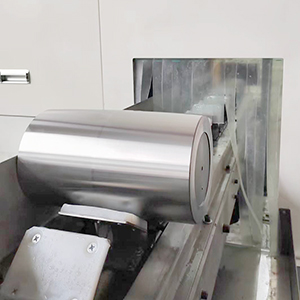

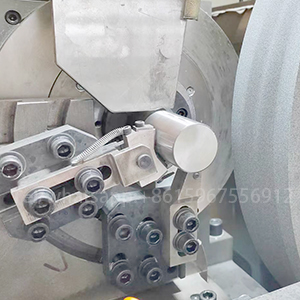

OD Grinder of big bearing rollers

The CNC OD Grinder of big bearing rollers has the most refined technology for max models for outer diameter of spherical rollers and cylindrical rollers and tapered rollers, the model can achieve the higher tolerance accuracy, such as roundness, roughness, surface, profile and linearity, and has higher precision, higher stability, higher efficiency in bearing rollers industry. the machine was widely used in airfield and rail field and wind energy field Etc.